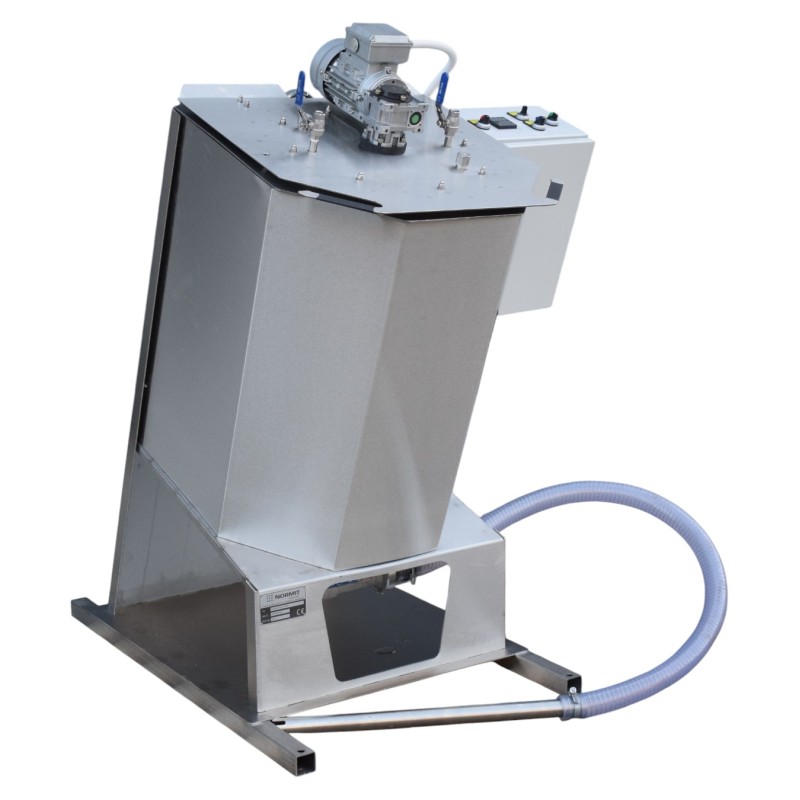

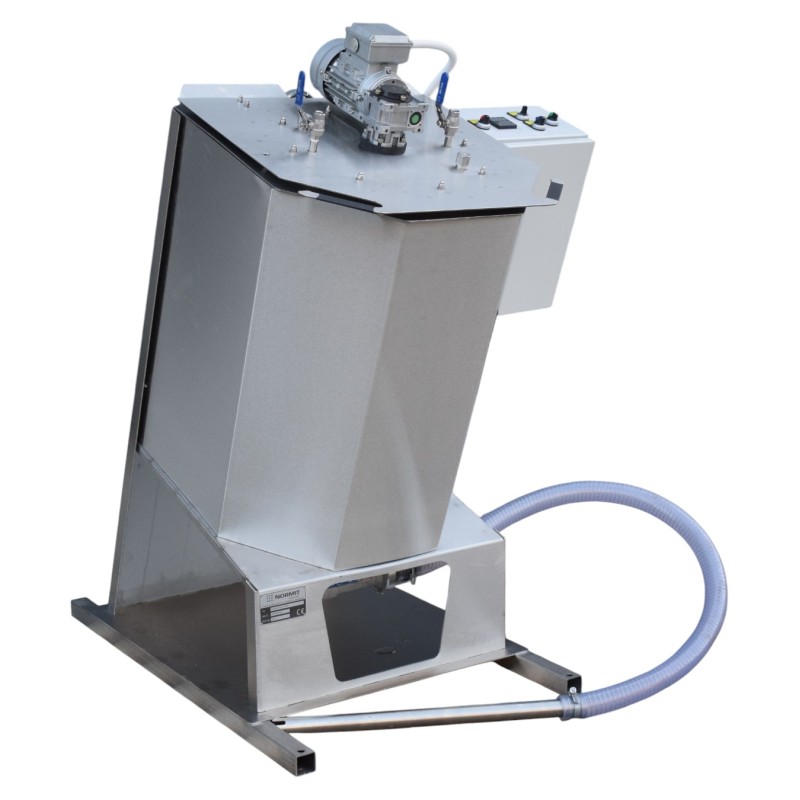

Vacuum cooker Ladia

Vacuum boiler Ladia is designed for cooking caramel, caramel mass, condensed milk, fondant as well as filling, jelly, marmalade and soft sweets.

The price is set for the 100l version, we also offer other volumes. It can be upgraded to a vacuum evaporator by installing a condenser.

Vacuum cooker Ladia is designed for cooking caramel, syrup, fondant as well as fillings, jellies, marmalades and soft sweets.

The vacuum boiler is manufactured for low or high temperature cooking in a wide range of goods - confectionery, jams, caramel, sauces, including high and low viscosity products.

Vacuum cooker can concentrate various extracts and similar ingredients in the food, pharmaceutical and chemical industries.

PROCESSES:

- mixing

- dissolution

- pre-cooking

- cooking

- deaeration

- caramelization

- tempering

Optionally it is possible to equip vacuum cooker with an ingredient dosing system (the basic equipment does not include this option).

ADVANTAGES of the vacuum boiler:

High quality finished product. Due to the special design of the cooking container, the process of removing moisture and caramelization takes place very efficiently, thereby reducing the time of cooking the confectionery material and thereby improving the quality of the finished product.

The use of vacuum allows cooking and evaporation of water at lower temperatures, thereby eliminating the burning of the product. The finished product has a naturally rich flavor with maximum preservation of aromatics. In vacuum cooking, thermosensitive substances can be added without losing their valuable and desirable properties, as is the case with atmospheric pressure cooking.

Economical. Effective heat transfer providing fast heating that significantly reduces the energy consumption for cooking in a single dose. Ease of use. The ingredients are inserted through the top lid. The finished product (dense mass) is conveniently unloaded through a highly hygienic bottom drain valve.

Hygiene. Vacuum cooker construction is suitable for cleaning and maintenance. It is highly hygienic, without dead zones. CIP Cleaning. The automatic control system controls all processes according to prescribed recipes

You might also like

The stated price does not include the steam generator

The unique sectional cooking kettle is intended for high-performance cooking/blanching/frying of a wide range of products with subsequent cooling to avoid damaging their structure. An essential part of this technology is the efficient cooling section, necessary for halting the cooking process after unloading. This function is also necessary when processing vegetables to the "aldente" state, when vegetables retain their structure and natural color after thermal treatment. This model provides heating by direct injection of purified steam into the heating section (steam generator - option).

- Suitable for cooking small-sized products

- Fast and intense heating due to direct steam injection

- Intensive hydro-stirring

- Automatic basket lifting system

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 2x250l/ 3x250l

- Voltage: 380-400V

- Working volume: 2x175l/ 3x175l

Specialized vacuum cooking kettle for sweet masses, ideal for commercial applications and medium to large scale food production.

For a price quote, send us a request.

The compact line of double-type vacuum cooking kettles comprises a complex of batch food cooking units designed for periodic thermal processing, vacuum mixing, and deaeration of various products under sub-atmospheric pressure.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 2x300l/ 2x600l

Double-jacket stainless steel cooker for marmalade and jam production.

This premium cooking kettle is gas-fired and has a capacity of 120 liters. Ideal for preparing a wide variety of dishes.

For more information, please, send us an email to sales@vacufry.com

SnackPro blancher will prepare different types of products making it a great solution for blanching large volumes of fruits and vegetables in a short time.ô

For more information and price quote email us at sales@vacufry.com

We sell many different types of cooking equipment, with a mixer or without, tilting, electric/steam/gas heating system, and many different modifications.

For more information, send us an email at sales@vacufry.com

This multifunctional cooking machine is designed to be used in a variety of different ways and is suitable for the majority of professional kitchens and catering businesses - any small enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

For a price quote, send us an email at sales@vacufry.com

Complete set of equipment for processing shelled beans, and the production of a soy base with a capacity of 800-1000 liters per hour.

For additional information, contact us at sales@vacufry.com

Vacuum homogenizer VMG M is the ideal solution for the production of pilot batches and the industrial production of a wide range of products of small and medium production. The price depends on the production capacity.

For additional information, please contact us at sales@vacufry.com

The price is stated including the unheated conical side panels

The frying pan of the WOK type with direct electric heating is designed for fast and intensive heat treatment of products with a maximum heating temperature of up to 220 degrees. This equipment allows you to sautûˋ, fry, stew, boil, cook and concentrate various products, including thick and viscous ones thanks to the frame mixing device and an automatic tilting system for unloading the final product.

- Fast and efficient heating of up to 220 degrees

- Automatic tilting and unloading system

- Lid opening sensors for safe operation

- Safe steam exhaust system on the top lid

- Lid latches in the open position

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 45

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 46

- Voltage: 380-400V

Round cooking boiling pan combines together the advantages of cooking with automatic mixing. Designed for catering industry, school kitchens, restaurant kitchens or food industry. Capacity ranges from 100l to 500l. The available heating options are - steam boiling or indirect electric heating.

Wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments.

Price depends on the chosen option. Please email sales@vacufry.com

Unbeatable price for highest quality material, modern technology, cylinder design. We offer different capacity catering cookers, electric, steam or gas.

If you need different capacity, please email us at sales@vacufry.com

A vat or cooking kettle for milk is a large container or vessel used for heating and processing milk, typically in dairy production, to pasteurize, cook, or produce various dairy products such as cheese or yogurt.

For more information or a free consultation, please contact us at sales@vacufry.com

The price is set for the basic version of the reactor without additional options and the control panel

The vacuum vessel with a coolant duplicator and a mixing device is a universal solution for processing various products at sub-atmospheric pressure. Based on this simple device, you can select and modulate it into complex installations such as aô vacuum evaporator, aô vacuum cooking kettle, and aô unit for the production of cream honey.

- Sloped Design - Gravity Mixing

- Bottom valve DN40 included in the basic version

- Small-volume duplicator - low costs for coolant heating/cooling

- Modular system: customization of the equipment and its functionalities by ordering additional options

- An easy to disassemble mixing device

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The price is indicated for the basic version of the set of equipment with a homogenizer

The equipment for the production of ice cream mixtures is based on a universal vacuum reactor with a coolant jacket and a multi-stage dispersant/homogenizer in an external circulation loop.

- Special type of a stirring device for easy disassembly and cleaning

- Processing with minimal product loss

- The bottom outlet valve is included in the basic version of the installation

- Multi-stage disperser for intensive wetting and homogenization of the flowing mixture

- External circulation circuit with a three-way valve for operation/washing of the equipment

- Reinforced agitator drive for thick and viscous mixtures

- Built-in vacuum pump

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Total power, kW: 3

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The universal bath pasteurizer is used for processing a wide range of different food products, such as ready meals, sausages, hams or liquid products. Effective temperature regulation and a hygienic stainless steel design.

More information: sales@vacufry.com

Smoking and cooking chambers are designed for thermal processing of meat, sausages, poultry, fish and cheese. You can smoke, steam, dry, bake and cool products up to 120 degrees in our chambers. Smoking chambers are made in four types of supply: oil, gas, electricity and steam.

For more information, send us an email to sales@vacufry.comô

Atmospheric cookers ASC are designed for efficient mixing, heating and cooking products for food and cosmetic industries. Volume, l: 100 l.

For a price quote, send us an email at sales@vacufry.com