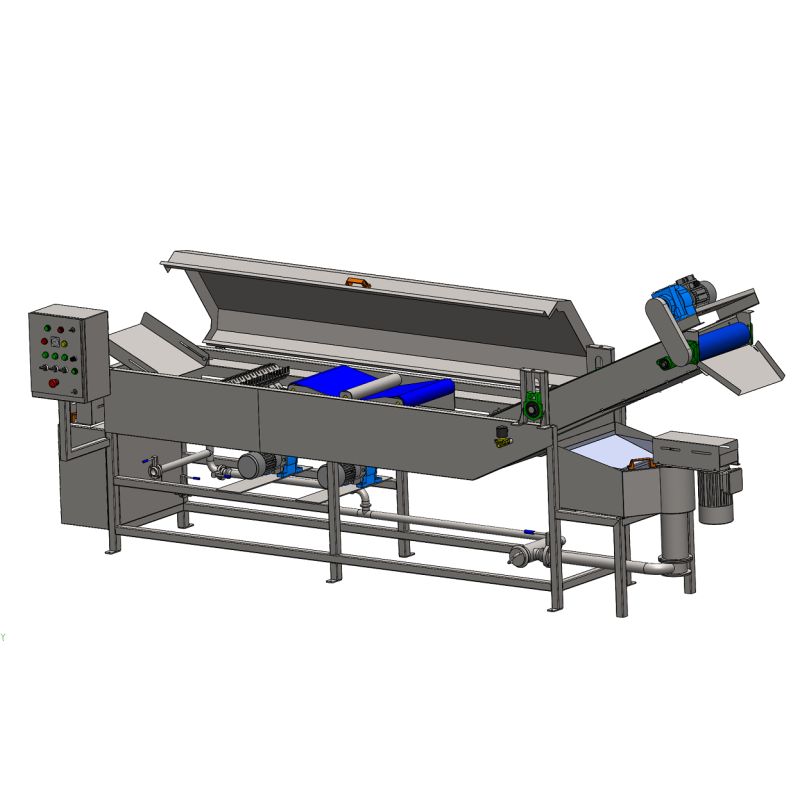

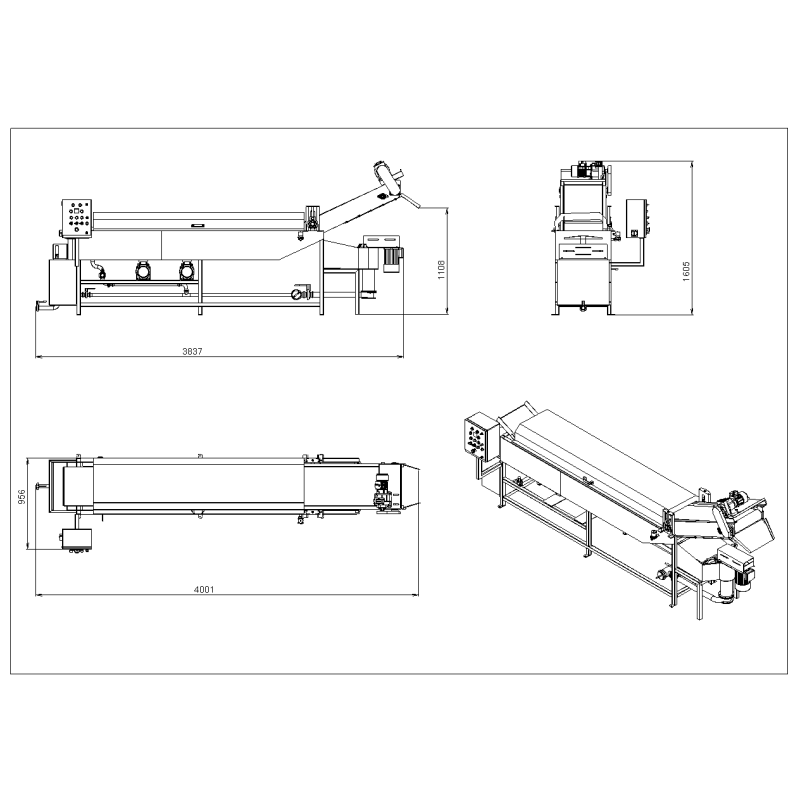

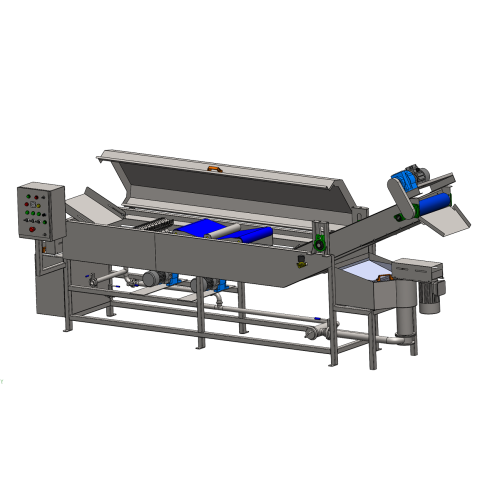

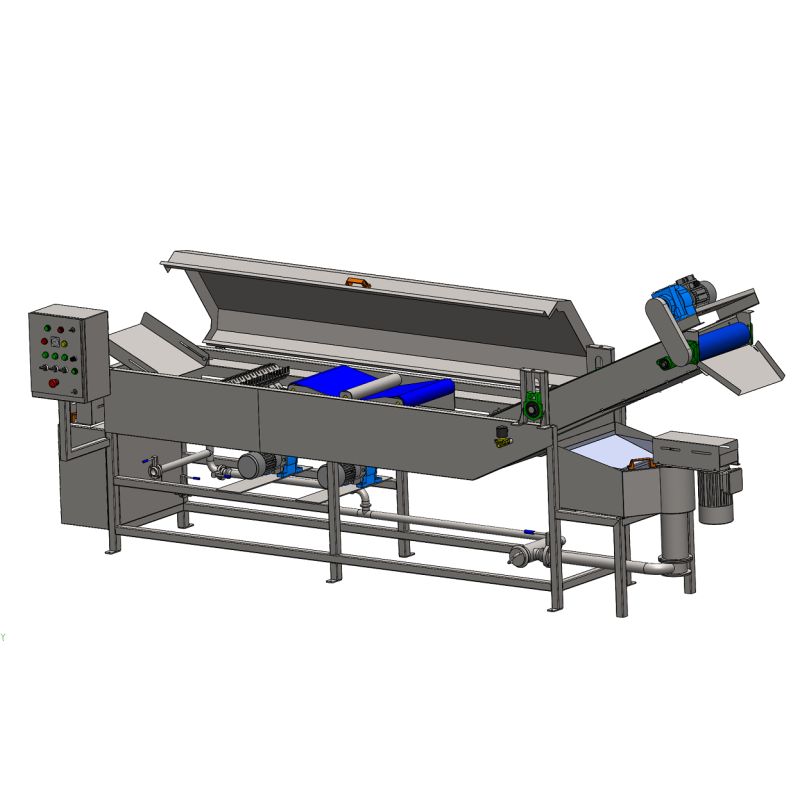

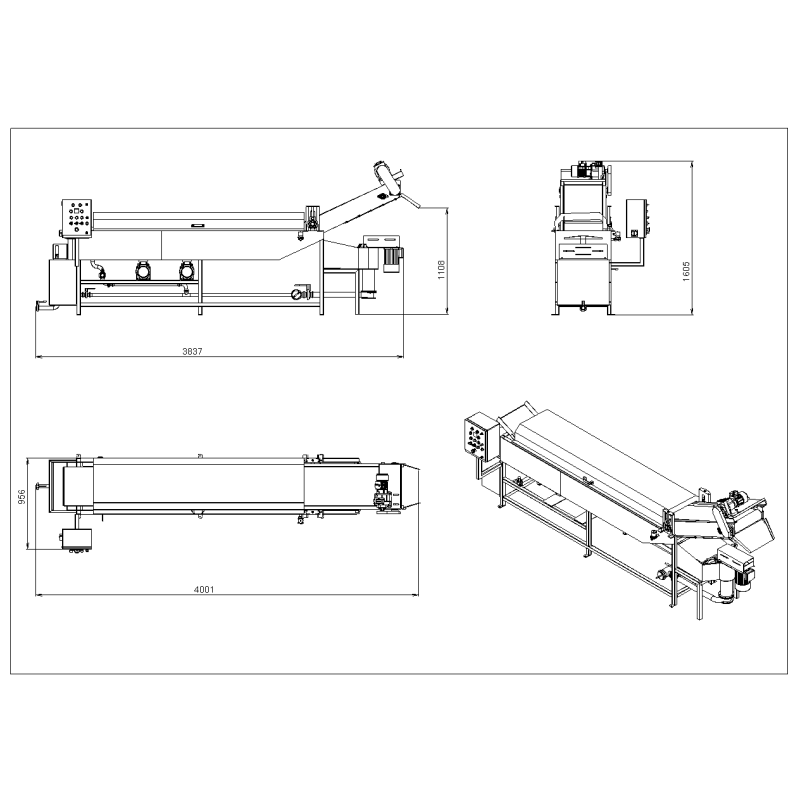

Continuous fryer for onions, nuts ODF 50

This continuous conveyor deep fryer is a reliable and versatile solution suitable for high-performance frying of a wide range of products by immersing them in hot oil.

- Universal application

- Quick transition for frying new types of products

- Possibility of using special frying modes

- Minimal amount of oil in the system

- Trouble-free oil filtration

- High oil exchange ratio

- High efficiency and productivity with compact design

- Manufactured to the highest quality standards using materials and components made in Europe.

Continuous fryers use the method of immersing the food products in oil at an adjustable depth, making them ideal for frying meat, fish and vegetable products, as well pastry products and processed snacks, including products with a hard or fragile structure, with or without breading.

With this continuous fryer you can easily fry foods such as:

|

|

|

|

|

|

|

|

|

|

|

|

Advantages

- Universal frying equipment, quick transition between switching to frying new types of products, the ability to use special frying modes.

- Minimum amount of oil in the system, uninterrupted oil filtration, high oil exchange rate - in most cases there is no need to exchange the oil due to it's rancidity, and only fresh oil needs to be filled into the system.

- High efficiency and productivity in a small area.

- Manufactured to the highest quality standards using materials and components made in Europe.

Operating principle

Continuous fryers use a method of immersing food in oil at an adjustable depth which is ideal for frying meat, fish and vegetable products, as well as snacks out of dough and various processed foods with a hard or fragile structure, with or without breading.

Products are fried by immersing them in hot oil and moving through the work bath on a single conveyor belt. A distinctive feature of conveyor fryers is the ability to easily adjust the level of immersion of the conveyor belt in oil. The adjustment accuracy is 0.1 mm, which allows you to fry products of different heights using this one fryer. The product moving along the conveyor belt does not float while being completely immersed in oil at a predetermined level. The adjustment of the immersion depth occurs smoothly and only takes a few minutes, which allows you to move on to frying other types of food without wasting time.

Hot oil circulates vigorously between the heating system and the product, with the oil flowing towards the product. The oil releases its thermal energy very quickly into the product, thus providing a heat load similar to what the product would be subjected to if it were constantly stirred in hot oil. The oil is filtered continuously using stainless steel filters with replaceable stainless cartridges. Deep fryers can be equipped with an electric heating system.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

You might also like

The AISI 304 stainless steel oil drain system is suitable for use with most deep fryers. It allows you to filter the oil directly when draining it from the fryer.

- Material: Stainless steel

- Weight: 13,5

We can help you choose the right continuous fryer suited for your needs.

For a free consultation or a quote, please send us an email atô sales@vacufry.com

The price is set for the combination of a basic fryer model and an additional module with rotating paddles.

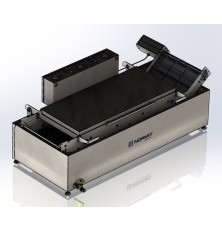

The universal modular fryer equipped with an additional paddle module is designed for frying thin slices of products that require immersion beneath the oil level.

You can send us a request atô sales@vacufry.com

- Adjustable frying time from a few seconds up to an hour

- Compact, tabletop version

- The paddle conveyor is installed on top of the basic fryer

- Safety thermostats on each heating element

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

Our continuous fryer is ideally used for frying escalopes, potatoes, croquettes and many other products.

Multifunctional pans function as a frying, cooking, and mixing device in one installation.

For more information on our automatic Wok-style frying pan with a built in mixer, please contact our sales department at sales@vacufry.com

We have various types of continuous or batch fryers. Just tell us what kind of product you wish to fry and we will help you choose the right deep fryer.

For a quote or additional information, send us an email at sales@vacufry.com

An adjustable electric donut fryer with a continuous conveyor system is specially designed for small confectionery shops, pastry production and catering establishments. It is capable of frying a variety of products similar to donuts.

For more information, please contact us atô sales@vacufry.com

The paddle module for the 400/1100/12 Universal Tabletop Modular Fryer is a conveyor with specially curved paddles for gentle frying of fragile and light foods.

For additional information, please contact us at sales@vacufry.com

We offer different types of continuous fryers, let us know which product you wish to fry and we will help you choose the right fryer for your business.

For more information, contact us at sales@vacufry.comô

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

The continuous pouring fryer is designed to fry meat, fish, vegetables and pasta products as well as chicken drumsticks, cutlets, nuggets, croutons, sliced zucchini or eggplant, and etc. using immersion frying and hot oil pouring methods.

For more information please send us an email atô sales@vacufry.com

A pouring fryer is a specialized equipment used in commercial kitchens for frying foods using a continuous pouring method. It offers precise control over the frying process by continuously pouring oil over the food, ensuring even cooking and consistent results.

Price depends on the chosen option. Please email sales@vacufry.com

Production line for vegetarian vegetable-based formed or molded products such as falafel. The line is based on the classical method of producing semi-finished products for their subsequent freezing and packaging.

- Compact line suitable for both professional kitchens and industrial production.

- Fully automatic operation with minimal manual labor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

Semi-automatic donut fryers are extremely efficient machines designed for easier donut production.

The combination of the compact 400/1100/12 fryer with the secondary upper pressure conveyor, allows you to expand the variety of products that can be fried on it. It ensures uniform, high-quality frying of fresh and semi-finished products in small to medium scale, making it suitable for small-scale production, professional kitchens and street food businesses. The fryer fully submerges the product in oil throughout the whole frying process with the help of the second pressure conveyor that forces the product beneath the oil's surface.

- The maximum height of the fried product is - up to 50 mm

- Immersion thermometer for visual monitoring of the oil temperature

- Frying time can be set from a few seconds up to an hour!

- High temperature ã up to 200C

- The conveyor belt is made out of a food-grade stainless steel thin mesh

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

The digitally controlled continuous conveyor system ensures the frying of a wide range of products at a consistent level. Thanks to the possibilities of deep frying, this model is suitable for a wide range of products from spring rolls, onion bhajis and falafel to fish fingers, burgers and chicken nuggets. The fryer is available in widths of 200, 300, 400 and 600 mm.

For additional information, please contact us at sales@vacufry.com

Automatic donut fryers are extremely efficient machines designed for easier production of doughnuts.ô

The series of Continuous Fryers Pour Oil is the boom in the market of frying and roasting equipment. The new construction designed by our engineers, based on existing practical experience in the production and use of conveyor fryers, provides the best example of environmental friendliness.ô

For more information please emailô sales@vacufry.com