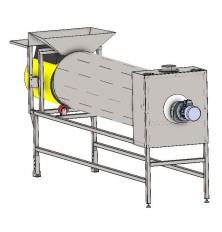

Air cooling conveyor CAC O 500/1700

An air cooling conveyor is a system that uses moving belts and airflow to cool down products as they are transported along the conveyor line.

For additional information or a price quote, send us a request.

The CAC series air cooling conveyors are designed for intensive cooling and removal of excess water or oil (air knife section) from products after frying, cooking or blanching by blowing air at ambient temperature.

Normit CAC refrigeration conveyors effectively reduce the temperature of the product (in most cases in a few seconds), thus stopping their cooking. The product is cooled to a temperature suitable for packaging.

It is intended for pre-cooling after cooking or frying vegetables and fruits, meat, fish and seafood and other products in three-packs or without.

Examples of applications:

- Nuggets

- Biscuits and chips

- Meat patties

- Blanched dried fruit

- And other

The design of the cooling conveyors ensures optimal air distribution over the entire surface of the conveyor belt. A high-performance industrial fan with power regulation is located in the lower part of the conveyor which is part of the system. With the help of a frequency converter, it is possible to regulate the belt speed and thus influence the cooling time.

You might also like

The inspection conveyor is designed for inspection and manual removal of unsuitable pieces of root vegetables, fruits and berries.ô

Air cooling conveyor with MULTI AIR KNIFE is a system forô intensiveô removing excess water or oil and preliminary cooling.ô

It is intended for pre-cooling after cooking or frying vegetables and fruit, meat, fish and seafood and other products.

For a price quote or more information, send us a request at sales@vacufry.com

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product as well as size of the conveyor.

Washing tank with wheels with conveyor belt for fruits and vegetables. For more information, send us an email to sales@vacufry.comô

The vacuum crystallizer-cooler is specifically designed for sweetened condensed milk. Crystallization with cooling is one of the most important stages in the production of condensed milk according to GOST and is necessary before dosing and packing the finished product.

- After crystallization, condensed milk has a delicate structure with small crystals

- Condensed milk has a homogeneous shape and attractive consumer properties

- The shelf life of condensed milk is extended without changing the quality of the product

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The vacuum homogenizer is designed for whipping mayonnaise, ketchup, various sauces, confectionery pastes and fillings, condensed milk, jams and marmalades, canned goods, as well as similar liquid or pasty products with a homogeneous structure.

- Homogenizer in an external circulation loop

- Built-in vacuum generation and retention system

- Modular design with numerous options

- Possibility of automatic dosing of ingredients (optional)

- No additional pump required for loading/unloading

- Automatic top cover lifting system

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 13,5

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The IBC container insulation cover is designed for use in ice water stations with IBC containers to maintain the cold coolant at a set temperature.

- Allows you to reduce energy costs of the refrigeration machine - chiller

- Protects from short-term fluctuations in ambient temperature, reflects sunlight (up to 97%)

- The cover is easy to install, with valve holes are installed with hook-and-loop fasteners (Velcro)

- Type of the equipment: Optional equipment

This multi layer belt dryer with integrated cooling system works as a dryer and cooler in one installation.

For a price quote or more information, email us at sales@vacufry.com

Air cooling conveyor with MULTI AIR KNIFE is a system forô intensiveô removing excess water or oil and preliminary cooling.ô

Lowering the temperature and humidity protects the product even without chemical treatment. The device is also used for continuous air cooling after heat treatment.

For more information about the cooler, contact our sales department at sales@vacufry.com

The water chiller CHWHE consists of a cooling unit in the upper part and a pump plus isolated water tank (made of stainless steel) in the lower section. We offer different capacities.

If you have any questions, email us at sales@vacufry.com

Vacuum homogenizer VMG M is the ideal solution for the production of pilot batches and the industrial production of a wide range of products of small and medium production. The price depends on the production capacity.

For additional information, please contact us at sales@vacufry.com

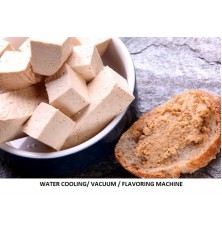

The vacuum diffusion cooling unit is a multifunctional device not only for vegan processors.

For more information, please contact our sales department at sales@vacufry.com

ACM mixing tank is intended for efficient cooling, heating, tempering and storing of mayonnaise, sour cream, chocolate, oil and similar products after their production.

For more information, send us an email at sales@vacufry.com

CAC Air cooling conveyors are designed for intensive cooling and removal of excess water or oil (air knife section) from products after frying, cooking or blanching.

For additional information, please contact us at sales@vacufry.com

The cooling units have a compact design. They are space-saving and easy to assemble. The chiller in standard version can work at water outlet temperatures from +10ô¯C to +25ô¯C.

For more information, send us an email to sales@normit.comô

A chiller is a cooling machine that removes heat from a liquid through vapor compression and absorption in a cyclic manner.

For additional information, please email us at sales@vacufry.com

The KWS mixing vessel is engineered for versatile operations, including heating, cooling, and mixing of liquid products, with a maximum temperature capability of 60 ô¯C.

For a price quote, send us an email atô sales@vacufry.comô

Fixed cooling unit wit different capacities from 67 kW up to 226 kW. Unit are solid and ensure long-life base operation.

For more information about the chiller, please contact our sales department at sales@vacufry.com

The NWT PLUS chillers have a compact design. They take little space and are very easy to install and to start. The units are mobile on wheels. We offer different capacities.

For more information, email us at sales@vacufry.com