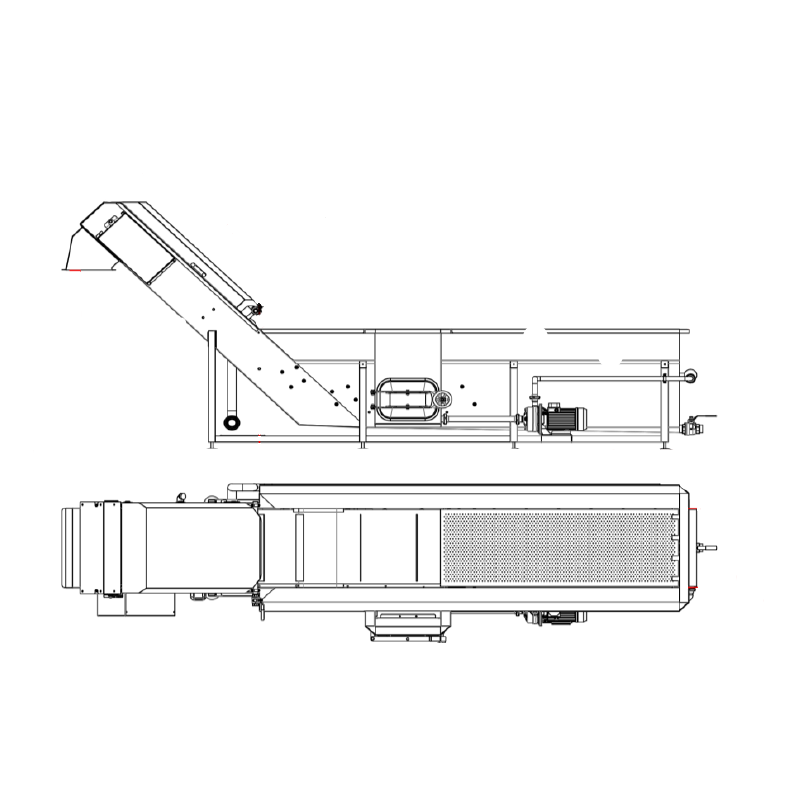

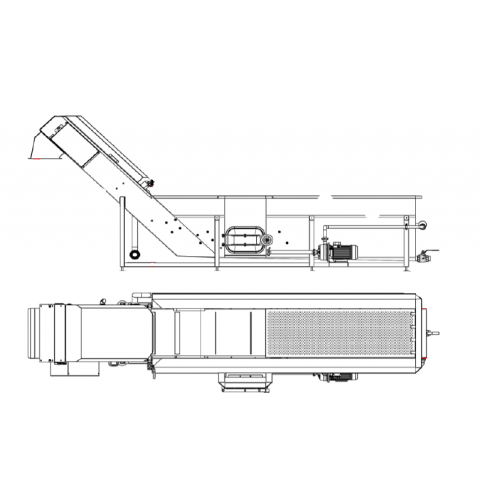

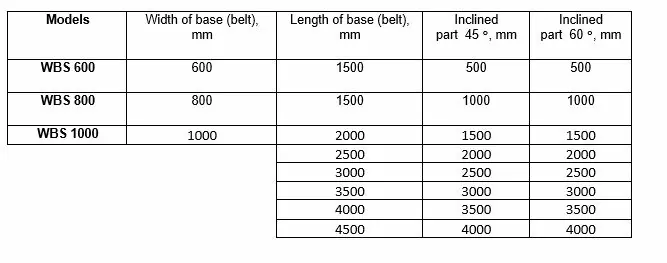

WBS bubble washers belong to continuous washing equipment and are used for cleaning fruits and berries before processing.

Bubble washers are designed for efficient and gentle washing of a wide range of fruits and berries with a delicate structure by sparging the working fluid (passing gas under pressure through the working fluid).ô

The washers of this type are equipped with the integrated transporting conveyor for transporting the product from the washer to the next processing phase. They have a function of gradual exchange of water during washing: inflow of fresh water at the exit of fruits from washer, outflow of waste water at overflow at the entrance of fruits in the washer.ô

Principle of operation:

The raw material is loaded into a bath filled with water, where, using a turbulent flow of water, it mixes and washes. It is pushed out by air bubbles and immersed in water again. Thanks to the used system the surface of the fruits and berries cleans gently without any damage. Due to the internal system of water circulation, the washing intensity increases and the raw material moves along the washing batch to the conveyor, which is equipped with an additional rinse system.ô

When the product gets on the integrated transporting conveyor, it moves upward, where an additional rinse system sprays the product with water again. Thereafter the raw material unloads automatically and goes to the next processing phase.ô

Products:

- cherries

- grapes

- peaches

- apricots

- pears

- apples

- nectarines

- kiwi

- lychee

- nuts

- sunflower seeds

- pumpkin seeds

- and many others

Benefits:

- Hygienic Design

- Gradual exchange of water during washing

- Low water and energy consumption

- Easy cleaning of the whole washer after use

- Speed regulation with frequency converter

- Simple and continuous operation

The bubble washers are available in several modifications:

Our tunnel container washers are designed to wash different kinds of plastic containers.

Fruit washer is designed for washing and cleaning products such as fruit or vegetables before processing, especially apples.

If you're looking for any other fruit and vegetable washers, send us a request.ô

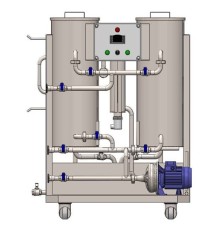

CIP station CIP-101 With a usable capacity of 1û100 liters, it is used for cleaning, sanitizing and sterilizing vessels and pipes in a brewery. This type of CIP station is recommended for cleaning and sanitizing tanks from 0 to 4000 liters.

The container washer for canned food is a specialized washing system designed to thoroughly clean containers used for canning food products, ensuring hygiene and sanitation standards are met within your food processing facility.

Price on request. E-mail sales@vacufry.com

The brush washer/scraper is an industrial device for washing and scraping root vegetables depending on the degree of contamination.

For more information, contact sales@vacufry.com

The destoner lift machine is designed for pre-washing and transporting root vegetables such as potatoes, carrots, beets, and other similar vegetables. After rinsing, the auger destoner separates floating particles like leaves and stems in the receiving hopper, while the product is conveyed up to the discharge height using a screw lift.

- Allows you to separate stones, leaves from root vegetables

- Pre-washing of root vegetable crops

- Two functions in one unit: washing and transporting

- Spacious hopper/tub for loading the product

- Material: Stainless steel

- Principle of operation: Continuous mode

Semiautomatic production line for washing and destoning apples. Approximate capacity 1000 kg/h.

For more information or a price quote, please contact our sales department atô sales@vacufry.com

The washer with external loading conveyor UNI M is specifically designed for the efficient and high-performance washing of vegetables, potatoes, and fruits, using gentle exposure to water to ensure thorough cleaning without harming the product.

Price on request. E-mail sales@vacufry.com

CIP-201 - installation for cleaning and disinfection of vessels and pipelines in breweries and other food industries with one tank of 200 liters.

Keg washing and filling machine used for washing and filling kegs and barrels for beer, cider, wine and other beverages.

This machine allows washing and sterile rinsing with dry steam of cans and cups before filling them with product.

For a free consultation, send us an email at sales@vacufry.com

Vegetable washers are designed to clean and prepare vegetables for consumption or further processing.

We offer different types of vegetable washers, for a price quote or for a free consultation, send us an email at sales@vacufry.comô

Improve the cleaning process with the CIP-53, a mobile station designed for thorough sterilization and sanitation of vessels and pipelines. Ideal for breweries and the food industry, this comprehensive system with three 50 or 100 liter tanks ensures efficient cleaning of fermentation and storage tanks, offers digital temperature control and neutralization.

CIP-52: Clean-In-Place - Machine for cleaning and the disinfection vessels and pipelines in breweries and other food processing plants with two 50 liter tanks.

CIP-202: Cleaning-In-Place - Machine for cleaning and disinfecting vessels and pipelines in breweries and other food processing plants with two 200 liter tanks.

Wheat washer, huller and separator is used for the preparation of grain for milling. Price depends on your production capacity.