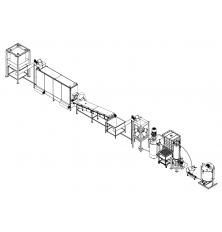

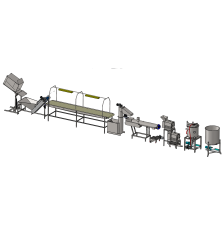

Hamburger production line is designed for production of hamburgers or veggie burgers.

The line produces from 2.000 up to 6.000 hamburgers per hour.

THE BURGER LINE CONSISTS OF 2 MACHINES:

- Mini automatic batter - breading machine

- Automatic hamburger machine

Automatic hamburger machine â technical specification

- Can be connected to any filler.

- Forms hamburgers (without paper).

- Variable shape (round, square, oval, rectangular).

- Round hamburgers from 60 up to 110mm.

- Pneumatic operation (consumes 250 liters per minute).

- Working pressure: 6kg /cm2.

- Electrical power consumption: 100 watt (3-phase).

- Made in stainless steel.

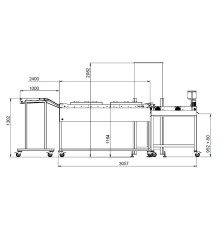

Mini automatic batter / breading machine â technical specifications:

- Automatic battering and breading.

- Speed variable from 9 to 15m per minute.

- Electrical operation (single-phase 220 volt).

- Motor power: 250 watts.

- Inverter for discharging bread.

- Blower for excess liquid.

- Pieces drop into the belt or go down ramp to remove excess bread.

- Support for trays at exit.

- Mounted on 4 legs with stainless steel wheels.

- Can be fully dismantled for easy cleaning.

- Made in stainless steel and non-toxic plastics (suitable for the meat industry).

- Maximum robustness and durability.

- Easy maintenance.

- Low price.

You might also like

Hydraulic piston fillers for the food processing industry, filling machines for meat and sausages, ideal equipment for meat industry producers and butchers.

For additional information, please contact us at sales@vacufry.com

- Productivity: 20 l

Batter breading machines are designed for batter breading products such as meatball, hamburgers, soya, vegetarian burgers, croquettes, vegetables and other products. Whether you are a small kitchen or have bigger production capacity, we are able to offer complete solution.

The price depends on your production capacity.Â

Whether you are a small kitchen or have bigger production capacity, we are able to offer complete solution.

Croquettes production line for making and batter breading croquettes, preparing them for frying. Croquettes from 15 to 55 grams. Produces up to 12,000 pieces/hour. We also offer a range of fryers.

Price depends on your production capacity. For more information, please contact our sales department at sales@vacufry.com

The extended version of the modular conveyor fryer with a large number of optional accessories, significantly expands the production capacity for deep-frying various products by increasing both the frying area and heating power.

- Frying time can be adjusted from several minutes up to an hour!

- Overheating safety sensors are installed on each heating element

- Compact support structure on a mobile support

- Fine-mesh conveyor grid allows for frying small and fragile products

- A large number of additional options in the form of automatic oil top-up system, loading conveyor, filtration system, cooling conveyor, etc.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 24

- Country of origin: Slovakia

- Working Area Width: 400 mm

- Voltage: 380-400V

Production line for vegetarian vegetable-based formed or molded products such as falafel. The line is based on the classical method of producing semi-finished products for their subsequent freezing and packaging.

- Compact line suitable for both professional kitchens and industrial production.

- Fully automatic operation with minimal manual labor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

Semiautomatic production line for washing and destoning apples. Approximate capacity 1000 kg/h.

For more information or a price quote, please contact our sales department at sales@vacufry.com

An equipment complex designed for processing raw, peeled, and blanched peanuts, offering a production capacity of up to 500 kg/hour.

A continuous production line for deep-frying semi-finished products.

- Frying products both below and above the oil level is possible thanks to the option to select the type of the upper conveyor or easily replace it with another one, depending on the product.

- The frying time can be adjusted from just a few seconds up to an hour, allowing you to fry products with varying frying durations, something that is nearly impossible with any other continuous conveyor fryer.

- Compact design, it includes all essential processes, such as oil storage and filtration.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 400 mm

- Voltage: 380-400V

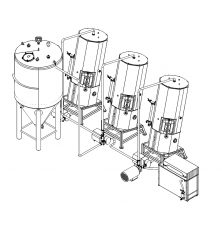

Equipment for the production of condensed milk from pre-pasteurized milk. This equipment can be manufactured with a capacity of 50 to 500 kg/hour, or on request. We also manufacture condensed milk lines according to TU from dry milk or normalized milk concentration lines.

This set of equipment for the production of condensed milk from dry components by restoring the milk. This production line can be manufactured with a capacity of up to 500 kg/h or can be customized based on specific requirements.

For more information and detailed inquiries, please contact us at sales@vacufry.com

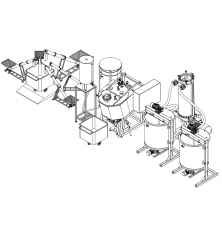

This equipment complex enables the production of Nutella-type chocolate pastes with a capacity of up to 250 kg/h.

For additional information, please contact us at sales@vacufry.com

This jam production line allows you to get ready-made jam at the exit from whole fruits at the entrance! Equipment options may vary depending on the customer's technology.

For additional information, please contact us at sales@vacufry.com

Our hydrodynamic extraction line is designed for extracting various components from plant materials, including biologically active substances, proteins, fats, carbohydrates, antioxidants, dyes, and flavors.

- Effective âsoftâ continuous hydrodynamic extraction â percolation from finely crushed raw materials.

- Extraction without the need for pre-drying the product, resulting in savings on labor and energy costs.

- Utilizing raw materials without heat treatment, preserving all of their valuable substances and enzymes.

- Possibility of performing vacuum-pulse extraction (optional).

- Additional income from processing âwasteâ products - extracting valuable components from pulp and pomace.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The set of individual equipment for the production of French fries may differ depending on the initial raw materials. We offer various modifications from washing to frying with subsequent dehumidification starting from 50 kg/h for the final product.

For more information, please contact us at: sales@vacufry.com

A complete set of equipment for the production of margarine with a capacity of up to 500 kg/hour.

For more information, contact us at: sales@vacufry.com

A production line for making puree from seeded fruits such as apples or pears with a processing capacity of up to 2000 kg/hour of raw materials.

- Productivity: 1000 kg/h/ 2000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

For the price quote or more information regarding this equipment complex for the production of chocolate, contact us at sales@vacufry.com

We offer equipment for processes such as: honey dissolution, honey drying, honey homogenization, honey pasteurization, honey creaming and honey packaging. The necessary equipment is selected by the customer based on the required processing technology for their manufacturing process.

More information: sales@vacufry.com