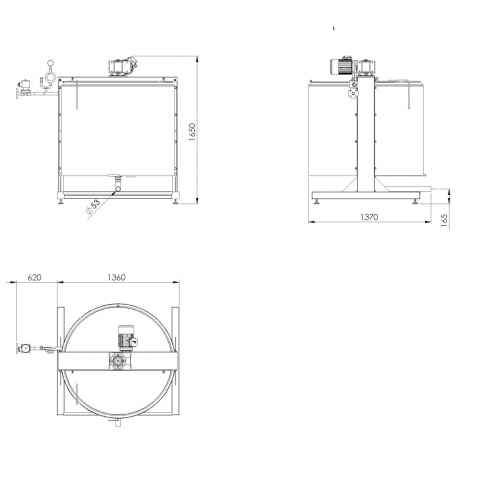

Cooking kettle Unicook S 1000

The atmospheric batch cooker model UniCook E or UniCook S, featuring a stirrer, is tailored to meet the diverse cooking needs of various food production businesses in industrial settings.

The cooking kettle is suitable for a wide range of liquid and paste like products with low to moderate viscosityô including those with solid inclusions.

Suitable products:

- Jams, preserves and marmalades

- Soups and semi-finished products

- Meat sauces, dressings, dips

- And similar products

If you want to cook your food at low temperatures, to better preserve the product's appearance and nutritional properties, or to add components that are sensitive to heat, we recommend using the UniCook universal cooking kettle.

The construction of the UniCook boiling kettle consists of a thermally insulated cylindrical container, a heating system and a slowly rotating frame stirrer with an upper drive. Optionally, the stirrer can be equipped with Teflon scrapers that effectively wipe the product from the walls of the container, thus preventing the product from sticking and burning to the walls of the tank, which also makes the subsequent cleaning of the device after operation more efficient.

The lid opens 1/3 for convenient loading of ingredients. The control system in the basic version turns the mixer on or off and digitally displays and controls the temperature.

Features:

- Efficient and fast heating with precise temperature control.

- The highly effective heat distribution system heats the product quickly and with minimal inertia, significantly reducing energy consumption.

- Thorough mixing for quickly achieving a homogeneous product structure.

- The special shape of the agitator effectively distributes solid particles into the product without damaging them.

- Jams, sauces, soups, and ready meals cooked in our UniCook cooking kettle have a homogeneous structure and an attractive appearance.

- Effective dissolution of soluble sugars and other components.

- The capability to evenly distribute even a small amount of ingredients.

Addition Options:

- An adjustable agitator speed

- Teflon scrapers for continuously cleaning the walls of the unit (if the product is prone to sticking or burning)

- Direct steam injection

An integrated homogenizer can be incorporated to create a homogeneous mass with a particle size of 3 microns. If there is a need to introduce solid inclusions into the homogenized mass, they are loaded into the vessel after the homogenization process is completed. Subsequently, the product undergoes thorough mixing before being discharged via a pump.

Technical Specifications:

- Dimensions: 1360x1370x1650 mm

- Total volume: 1000 l

- Heating: up to 0.5 bar

You might also like

Heating boilers are designed to cook sausages, hams and oÿ˜al. Technology for superior performance and hygiene.

For additional information, please contact us atô sales@vacufry.com

The electric cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, broths, pasta, milk dishes, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. The equipment is not suitable for roasting or baking.

For additional information, please contact us atô sales@vacufry.com

If you need to cook the product at low temperatures, to better preserve the appearance and nutritional properties of the product, or to add components that are sensitive to heat, we recommend using the universal TiltCook boiler.

For a price quote, send us a request at sales@vacufry.com

Double-jacket stainless steel cooker for marmalade and jam production.

Tilting pans with mixers cook the product with continuous stirring and subsequently discharge the food into receiving trolleys, ensuring the discharge spout remains at a constant height from the ground. Designed for the catering industry, large kitchens, school cafeterias, restaurants, and other food production businesses.

The tilting cooker is produced in 2 versions: with gas or electric heating. The pan is designed for use in the food, hospital, catering industry and in large kitchens for making pasta, stewing and frying meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, etc.

For a price quote, send us an email at sales@vacufry.com

The universal boiler with an integrated homogenizer and a capacity of 1200 liters is designed for efficient mixing, heating, cooking and homogenizing of products for food, pharmaceutical and cosmetic industries such as jams, marmalades, syrups, fruit juices, nectars, beers, creams, ointments, soaps and many others.

The Economy series of the cooking kettles comprise a thick-walled stainless steel container with an electric mixer mounted on the quick-release upper housing. The installation allows you to mix and stir products during processing. The thick bottom of the pot allows it to be installed on all types of heating surfaces (gas, induction or electric stove).

The Economy version is recommended for use with low-viscosity liquid products; If processing thick and viscous products is necessary, we offer the Premium version of the cooking kettle.

- Sandwich bottom (multilayer) for use on all types of hobs, including induction

- Quick release lid with an electric stirrer

- Safety grid under the upper hull hatch - safe handling when stirring

- Possibility of visual inspection through the safety grid during processing

- Safe loading of components even during mixing

- Material: Stainless steel

- Engine power, kW: 0,12

- Volume: 20l/ 50l/ 100l/ 150l

- Voltage: 220-230V

The vacuum evaporation unit is specially designed for thickening dense food products in industrial quantities. The evaporator can be used for the production of thick syrups, caramel masses, dense fruit masses, as well as for the production of pectin, or heat-stable fillings with a high productivity.

- High performance

- Rotary spraying system with a powerful electric drive

- Evaporation in a thin layer with a large heat transfer area

- Low investment installation costs

- Tangential entry for product swirling

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

The price is indicated without gastro containers

Use this all-stainless steel water bath for gradual heating or cooking. The device is equipped with a practical drain tap for easy emptying of the container and is suitable for use with gastronorm containers.

- Compact installation

- Simple controls

- Safe operation

- Wide range of applications

- Material: Stainless steel

- Principle of operation: Batch mode

- Voltage: 220-230V

A circulation-type vacuum evaporator refers to a combined version of an evaporator that also takes advantage of other types to improve evaporation efficiency particularly by reducing concentration time and when processing heat-sensitive products such as milk.

- The external circulation circuit with heating intensifies the cyclic evaporation process.

- The forced circulation system ensures a decrease in the risk of localized product overheating.

- The condenser enables a deep vacuum and maintains a low evaporation temperature.

- Utilizing a mixing device with a spray system facilitates product evaporation in a thin layer, mimicking a film-type evaporator.

- Heating: Steam

- Material: Stainless steel

- Country of origin: Slovakia

- Total power, kW: 2,4

- Voltage: 380-400V

The innovative cooking device combines the advantages of cooking with automatic mixing and compact dimensions.

Contact sales@vacufry.com for more information.

This kettle with a radiator cooling system ranging from 30 to 500 liters is ready to cook according to the principle of a water bath.

We offer different capacity vacuum cookers. For more details and price, please email us at sales@vacufry.com

We sell many different types of cooking equipment, with a mixer or without, tilting cookers, with capacities from 100 - 350 liters.

For more information, send us an email at sales@vacufry.com

If you need to cook the product at low temperatures, to better preserve the appearance and nutritional properties of the product, or to add components that are sensitive to heat, we recommend using the universal TiltCook boiler.

For a price quote, send us a request at sales@vacufry.com

The CH 300 Vacuum Cooking Equipment is a high-performance system tailored for professional kitchens and industrial facilities, streamlining production processes with its advanced vacuum and mixing technology, ensuring superior flavor and texture in food preparation.

A universal cooking & cooling system for preparing large batches of food and subsequently cooling them down to preserve their structure.

Price depends on the selected options. For more information, please send us a request.ô

Thanks to the indirect heating system, this kettle is ideal for cooking liquid dishes. It is completely made of stainless steel and equipped with a convenient drain valve.

For more information, please, send us an email at sales@vacufry.com