Expansion tank for the heating system

The expansion tank is an additional component of the heating system circuit, where flow-through electric heating is used as an independent closed system for heating the hot water, serving as a heat transfer medium circulating in the duplicator of food cooking boilers, reactors, pasteurizers, and other food processing equipment. In heating systems with water heaters operating at temperatures up to 110ô¯C, the expansion tank is necessary to accommodate the increased volume of the heat transfer medium as it expands when heated.

- Special high-pressure vessel ã allows to withstand pressure of up to 5 bar in the system.

- Allows the use of a heat generator with superheated water up to 110ô¯C.

- Has different volume options, depending on the volume of the heat transfer medium, selected additionally.

The expansion tank is used in heating systems with superheated water up to 110ô¯C for heating the thermal medium in the heating jacket (duplicator) of various cooking boilers, reactors, evaporators or pasteurizers.

A special expansion tank in the form of a high-pressure vessel is necessary to regulate the volume of water in a closed system during heating. The tank also helps maintain the pressure level in the system.

- Type of the equipment: Optional equipment

You might also like

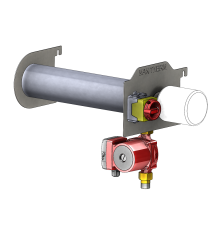

A flow-through water heater is a device for flow-through electric heating of water in heating systems for cooking boilers, evaporators and other units where it is necessary to supply a hot heat transfer medium - superheated water - to the heating jacket (duplicator). When choosing a flow-through heater, it is necessary to select a circulation pump based on the volume of the jacket or heat transfer vessel.

- The heater allows you to heat water up to 110 degrees

- Easily integrated into heating systems

- Has heating temperature regulation

- 2 stages of heating power adjustment

- Independent control panel with protection against overheating and "dry" running

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 2/ 3/ 6/ 9/ 10/ 12

- Principle of operation: Continuous mode

The circulation pump for the heating system is a mandatory component for the operation of a flow-through heating system used for heating the water serving as a heat transfer medium inside the duplicator of industrial cooking boilers, mixers, reactors, and vacuum evaporators in food production. It is selected based on the required parameters of the heating system (volume). Our specialists will be happy to assist you in selecting the appropriate pump if you provide the technical specification requirements. This pump is an essential additional component for the flow-through water heaterô up to 110ô¯C.

- It can be used to circulate water at temperatures up to 110ô¯ C

- High efficiency with low power consumption

- Also suitable for central heating systems, heated floors and even for solar systems

- Small connections allow the use of flexible pipes with a smaller diameter

- Type of the equipment: Optional equipment

In the production of condensed milk, a refractometer is used to accurately determine the solids content of the product, which is essential for meeting production standards and ensuring compliance with legal regulations.

The set consists of 20 shelves from AISI304 stainless steel.ô Additional option for MAK DRYER 7-14.

Additional option to VMG laboratory vacuum homogenizer 20/50.

Designed for the demanding requirements of the beer and beverage processing industry, this pressure suction food hose offers exceptional safety, durability, and compliance with international food standards. It is ideal for the transportation of high-quality raw, pasteurized, and organic beer, as well as a variety of other beverages, including wine, soft drinks, and alcoholic drinks.

Additional option for the VMG laboratory vacuum homogenizer 20/50.

Set of 4 height adjustable legs+/- 100 mm.

For more information contact: sales@vacufry.com

Optional module for the 400/1100/12 universal tabletop Modular Fryer - Pressure Conveyor for frying foods that require forced immersion in oil.

Supporting structure on wheels with locks (brakes), 2 swivel wheels, 2 swivel wheels with a brake.

For more information, contact: sales@vacufry.com

A thermometer is a precision tool used to measure product temperature in food processing, ensuring accurate control during cooking, mixing, and other food production processes. It helps to maintain consistency, optimize processing conditions, and meet safety standards in industrial food processing equipment like cooking kettles, blanchers and fryers.

A set of hooks for hanging and drying meat and fish. Additional option for the MAK DRYER 7-14.

For more information, please contact: sales@vacufry.com

The cyclone dust collection system is ideal for food processing facilities looking to prevent contamination by airborne particles, reduce product loss, and maintain a cleaner work environment.

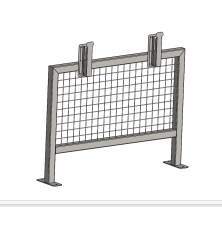

This rack is typically used as car mat holders at car washes. It can also serve as a universal stand for use in other enterprises.

A chiller is a cooling machine that removes heat from a liquid through vapor compression and absorption in a cyclic manner.

For additional information, please email us at sales@vacufry.com

Frequency inverters are used together with, and installed directly on equipment without the need to install additional electrical cabinets.ô

We also offer programming and installation of the frequency converter to ensure seamless integration and optimal functionality for your specific requirements.

For more information or to request more details contact: sales@vacufry.com

A set of additional paddles for transporting and unloading the product from the working area of ããthe universal 400/1100/12 fryer.

Protective decorative cover for colloid mill 132 (additional option)

For more information or to request more details contact: sales@vacufry.com